Fruit vinegar

Practical Action

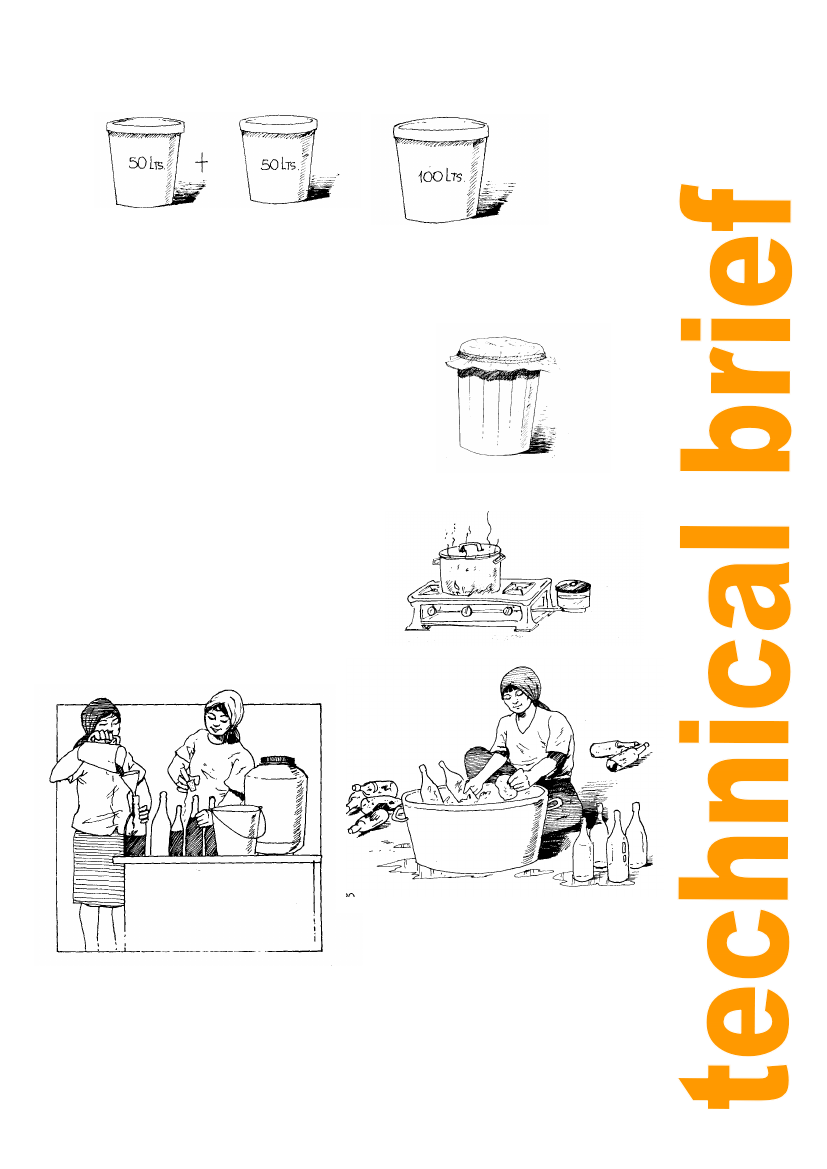

90 litres of vinegar for

consumption, (approx. 5%

acetic acidity).

boiled water = 100 litres prepared alcohol must

50 litres

of

alcoholic

must +

50 litres

of cooled

At this stage - obtaining the vinegar and adding more prepared alcohol must is carried out every

20 days.

Filtering

The vinegar is filtered after being separated from the

fermentation equipment. The filter is a layer of cloth with

two layers of cotton wool placed over the container.

Pasteurisation

The filtered vinegar is heated to 80°C for 15 to 20 minutes,

to avoid contamination and the development of more acid.

Bottle preparation

While the vinegar is filtering, the bottles can be

selected and washed. As the bottles used are

second-hand, they must be soaked in detergent

and one small spoonful of caustic soda. Then,

rinse with 1 small spoonful of bisulphate per 10

litres of water. Finally, stand them to drain.

Bottling

A clean funnel is used to fill the bottles and they are corked by hand.

For better presentation, put a plastic shrink sleeve over the cork.

Use 450 or 250 ml clear bottles.

7